If the starter isn’t performing, start with some basic testing:

Pretest Considerations: If possible, visually inspect the starter and/or interview pilots or operators for starting history. Indications of long cranking periods, burning odor or smoke from the starter, kickbacks, a cracked starter mount, a fast spinning starter with no prop movement, oil in starter, grinding noise, or a damaged ring gear are generally indications that the starter is in need of repair and the following tests will not be helpful. Jump to starter issues below for some guidance, but chances are you will need to replace or overhaul your starter.

WARNING: Before attempting any starter troubleshooting be certain to avoid standing in the propeller arc.

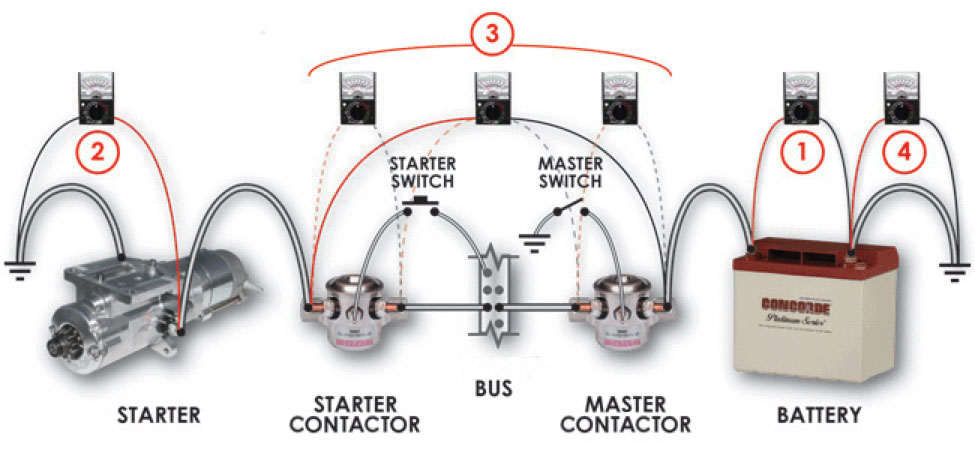

Test Procedure: The following testing procedure is most relevant to 12/14 and 24/28 volt Lycoming starters and some Continental starters that are low performing including slow cranking and/or failure to crank the engine over a compression stroke. If a starter is damaged by over-cranking or a stuck starter solenoid, voltage in step one may read below acceptable levels, thus incorrectly indicating a potential battery problem. Therefore, in such cases some consideration must be to the pretest conditions noted above, e.g., if it smells burned. If the only effect of energizing the starter results in an audible “click” with no prop movement, confirm step two to isolate the problem to the starter or starter contactor.

Record your test results below.

Result & Analysis

Questionable battery

See Testing Relevance above as a shorted starter will pull voltage down appreciably. However, if starter rotates at all, this is generally not a shorted starter condition.

Address battery issue – no need to proceed with remainder of troubleshooting.

Proceed to Step 2.

Record your test results below.

Result & Analysis

The starter needs 10V / 20V to operate properly. Suspect Cables, terminals and/or contactors.

*If the difference between Step 1 and Step 2 is more than 2 volts, Proceed to Step 3.

Voltage at starter remains above 10V / 20V and the starter doesn’t seem to be performing properly – replace starter or contact HET / Sky-Tec Product Support.

Record your test results below.

Result & Analysis

Correct any deficiency (terminals, contactors, switches).

Proceed to Step 4.

Record your test results below.

Result & Analysis

Clean or repair ground connections.

Replace starter or contact HET / Sky-Tec Product Support.

Common Questions

The Kickback Protection System or KPS® for the NL and NL/ec family of starters is through a field-replaceable shear pin. When energizing the starter, if the pinion engages the flywheel and the starter motor spins (or at least sounds like it is spinning), but the starter’s pinion gear does not rotate you should replace the shear pin. Follow these instructions.

In some cases, engine kickback will fracture starter drive gears. Kickback is related to engine set up and can be anything from incorrect timing to problems with the fuel system. If kickback is noticed as a common occurrence on the airplane, diagnose and repair the problem or the replaced starter drive may fracture again. Many of our current starters offer kickback protection and are warranted against damage due to an engine kickback.

This condition is related to the starter drive extension and retraction and affects all styles of starters. If, during normal extension, the gear does not extend completely, stress will be placed on the drive gear. If the starter drive does not disengage after start, the engine will tend to drive the gear placing stress on the gear and destroying the motor. In either case, the gear will rapidly wear or fracture.

Sticking mechanical starter drives, e.g., Bendix drives, should be cleaned with mineral spirits and only lubricated with silicone spray. Oil or common greases should not be used as they will attract and retain dust and grit causing the starter drive to stick or wear rapidly.

Solenoid-actuated starters do not require any type of cleaning or lubrication. If the starter is not going to be used for some period of time the shaft can be oiled to prevent corrosion.

There are two potential causes of this condition. If it is a mechanical starter drive (Bendix) and sticks intermittently, it most likely needs to be lubricated. This type of starter drive is initially lubricated to allow smooth operation. The drive gear must move in and out and also rotate. In use it can become dry and may begin to stick and fail to engage or disengage. We recommend lubricating this type of starter drive every fifty (50) hours of operation.

The other likely factor for intermittent engagement would be a faulty starter contactor. If you want to check a contactor, it is best to do so with a load applied. Resistance in the contactor, even a fraction of an ohm, is enough to produce poor or no operation due to the high current field. In a 12-volt starting circuit drawing 60 amps, for example, the addition of 0.2 ohms of resistance due to an oxidized connector or carbonized contact may drop the current to the load to 36 amps. This is a 40-percent loss in starter operating power caused only by a 0.2-ohm resistance.

Checking the circuit without a load would require that a lot of resistance be placed in line. The best method of checking the contactor is to disconnect the lead from the starter and connect it to a battery load-meter tester. Activate the contactor and check the voltage on each side of the contactor. A 0.1-volt drop is normal for a new or nearly new contactor. If you find any more than 0.3-volt drop, replace it.

For Continental engines, the most likely cause is a slipping starter adapter. This requires replacement or overhaul of the starter adapter.

This is normal for a permanent-magnet starter. Although power is removed by releasing the key/start button, a permanent-magnet motor will actually provide power to itself as it winds down and will keep the starter drive engaged for about a half-second until it loses sufficient RPM to fully disengage.

THIS CAN BE A DANGEROUS SITUATION. The starter contactors in many older aircraft may become welded shut after years of use. BE EXTREMELY CAREFUL. A starter contactor that is welded shut could cause the propeller to rotate when the master switch is energized, regardless of the position of the start button or switch. Replace the starter contactor. Your starter may have been damaged by this as well and may also need to be overhauled or replaced.

Lightweight starters do not have as much housing bulk surrounding them, so they aren’t as effective at insulating the gear train noise from the operator. To compound the issue, switching from a legacy heavyweight starter to a lightweight starter may also change the design style from a direct drive to a gear reduction drive in order to obtain the same drive torque. Gear-reduced starters have a much different noise signature than direct drive starters.